The Reality About AC Problems: What Actually Breaks and Why

The Reality About AC Problems: What Actually Breaks and Why

That Moment When You Know Something's Wrong

Last Tuesday, my neighbor Carol called me over in a panic. Her air conditioner was making this god-awful grinding noise, like someone was running marbles through a blender. She'd been ignoring it for three days, hoping it would stop. When I popped the cover off her outdoor unit, the fan blade was wobbling like a drunk person trying to walk a straight line.

Twenty minutes and one loose bolt later, her "emergency" was fixed. No service call needed. No $300 repair bill. Just basic maintenance she could've handled herself if she'd known what to look for.

This happens more than you'd think. People panic over AC problems that turn out to be simple fixes, or they ignore obvious warning signs until their system dies completely. After fixing air conditioners in Texas heat for fifteen years, I've realized most homeowners don't understand their equipment well enough to know when they should worry and when they shouldn't.

Your air conditioner isn't this mysterious black box that randomly breaks for no reason. It follows predictable patterns, gives clear warning signs, and usually tells you exactly what's wrong if you know how to listen.

The Ten Things That Actually Go Wrong

1. Weird Noises That Mean Something Specific

Air conditioners make noise. That's normal. What isn't normal is when your quiet system suddenly sounds like a construction site. Different sounds tell you different things about what's happening inside.

Squealing means your motor bearings are dying. These little metal rings keep your fan motor spinning smoothly, and when they wear out, metal starts grinding against metal. The annoying thing about bearing failure is how fast it happens. Monday you hear a little squeak during startup. Wednesday it's squealing constantly. Friday morning you wake up to no air conditioning because the motor seized.

I've watched people ignore squealing sounds for weeks, thinking they'll eventually go away. They don't go away. They get worse until something expensive breaks.

Grinding is worse than squealing because it means bearings have already failed completely. Your motor is now running metal-on-metal, destroying itself with every revolution. If you hear grinding, shut off your system immediately. Running it even one more day can turn a $150 bearing job into a $600 motor replacement.

Rattling can be anything from a $2 loose screw to a $3,000 compressor failure. Start simple - check that your outdoor unit sits level, tighten any obviously loose bolts, and make sure nothing's stuck in the fan. If rattling continues after these basic checks, you've got internal problems that need professional diagnosis.

Banging usually means your compressor is having problems. Compressors are the heart of your AC system, and when they start banging around inside their housing, replacement time isn't far away. Compressor replacement often costs more than the entire system is worth, especially on older units.

2. The Refrigerant Situation Everyone Gets Wrong

Here's what nobody tells you about refrigerant - it doesn't get used up like gas in your car. Your AC system is a closed loop. Refrigerant circulates continuously, changing from liquid to gas and back to liquid. If levels are low, you have a leak. Period.

Some contractors will just add more refrigerant when they find low levels. This is like putting air in a tire with a nail in it. You'll be back where you started within weeks or months, except now you've wasted money on refrigerant that's going to leak out again.

Refrigerant leaks are sneaky. Your system might cool fine for months while slowly bleeding refrigerant. Then one day when it's really hot outside, suddenly your AC can't keep up. By the time you notice the cooling problem, you've been paying higher electric bills for who knows how long because your system was working harder to compensate for the leak.

Signs you can actually see include ice forming on your indoor unit during hot weather. Seems backward, right? When refrigerant levels drop, your evaporator coil gets colder than it should, causing water vapor to freeze on contact. You might also hear hissing sounds near refrigerant connections or see oily stains around joints where leaks commonly develop.

3. Water Problems That Start Small

Your AC produces gallons of water every day in humid weather. All that moisture has to go somewhere, and when drainage systems fail, water ends up where it shouldn't be.

Most water problems trace back to clogged drain lines. These lines carry condensate from your indoor unit to the outside or a floor drain. Over time, they collect algae, dirt, and slime that eventually blocks water flow completely. When that happens, water backs up into your house instead of draining away harmlessly.

I've pulled some truly disgusting stuff out of clogged drain lines. Think swamp water with chunks floating in it. The solution is simple prevention - pour a cup of bleach down your drain line twice a year to kill algae before it becomes a problem.

If you see ice and water together, that's a different issue. Frozen coils eventually thaw, often producing more water than your drain system can handle. This flooding usually means you have airflow problems or refrigerant leaks causing the coils to freeze in the first place.

4. The Blower That Won't Shut Off

When your blower runs constantly, check your thermostat first. If the fan switch is set to "On" instead of "Auto," your fan will run continuously whether your system is cooling or not. This is the most common cause of constantly running fans, and it's free to fix.

If your thermostat settings are correct and the blower still won't stop, you probably have electrical problems with fan relays or control circuits. These components tell your blower when to start and stop, and when they fail, your fan might run continuously or not start at all.

5. Cooling Performance That Gets Worse Gradually

The most expensive AC problems are the ones that sneak up on you. Your system slowly loses efficiency over months, compensating by running longer and working harder. You adapt to slightly less comfort while your electric bills creep higher.

When your AC runs constantly but can't maintain the temperature you set, several things might be happening. Dirty coils make heat exchange less efficient. Refrigerant leaks reduce cooling capacity. Worn components work harder to achieve the same results.

Temperature variations between rooms often indicate ductwork problems. Leaky ducts waste expensive cooled air in unconditioned spaces like attics while allowing hot air to infiltrate your system. The Department of Energy says typical residential duct systems lose 20-30% of their air through leaks.

6. Dirty Coils That Cost You Money

Both your indoor and outdoor coils need regular cleaning, but they get dirty in different ways and cause different problems when neglected.

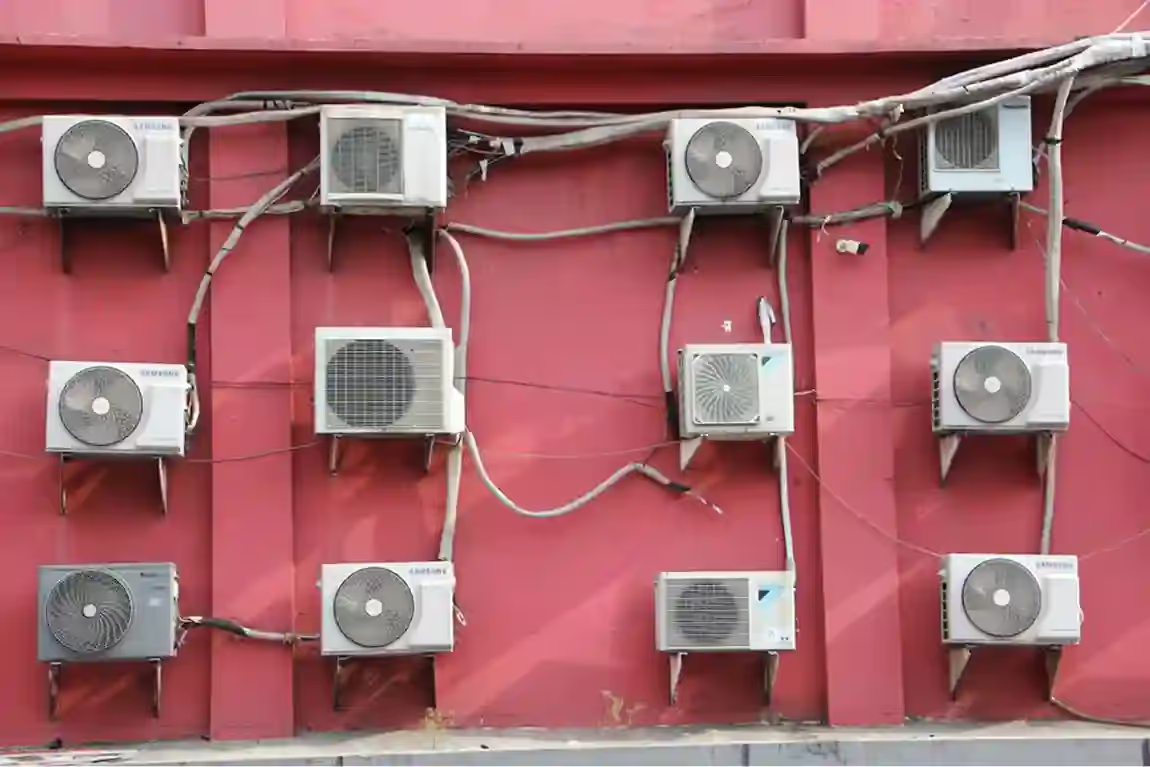

Condenser coils (in your outdoor unit) get clogged with dirt, leaves, grass clippings, and debris that blocks airflow. When these coils can't reject heat properly, your compressor works much harder, using more electricity and wearing out faster.

Evaporator coils (inside your house) collect dust and airborne particles that stick to their wet surfaces. Dirty evaporator coils can't absorb heat efficiently, reducing cooling capacity and increasing the risk of freeze-ups.

Dirty coils can increase your energy consumption by 30% or more while you barely notice any difference in comfort. This "dirt tax" shows up every month in higher electric bills.

7. Parts That Wear Out From Normal Use

Air conditioners have dozens of moving parts that wear out over time. Belts stretch and crack. Bearings develop play. Electrical contacts corrode. Motors lose efficiency. This is normal wear and tear, not manufacturing defects.

The key is catching worn parts before they fail completely. A loose belt makes noise but still works. A broken belt means no airflow and potential motor damage from overheating. Regular maintenance spots these issues while they're still cheap to fix.

8. Electrical Problems That Cascade

Electrical issues often start small and get progressively worse. A loose connection creates heat that damages nearby components. Corroded terminals increase electrical resistance, making motors work harder and draw more current.

If your system turns on and off rapidly (short cycling), electrical controls might be failing. If your circuit breaker trips repeatedly, something is drawing too much power. Don't just keep resetting the breaker hoping the problem goes away - you could end up with equipment damage or fire.

9. Sensors That Lie to Your System

Your thermostat sensor measures air temperature to determine when your AC should run. If this sensor gets knocked out of position, sits too close to a heat source, or fails mechanically, your entire system operates based on incorrect information.

Sensor problems cause systems to short cycle (run for very brief periods) or run continuously without maintaining comfortable temperatures. Sometimes sensors can be repositioned, but failed sensors need replacement.

10. The Maintenance That Never Happened

Skipping regular maintenance doesn't cause immediate problems, but it guarantees expensive issues later. Systems that get annual professional attention last longer, break down less often, and use less energy than equipment that only sees a technician when something breaks.

Professional maintenance catches small problems before they become disasters. Clean coils work efficiently. Proper refrigerant levels prevent compressor damage. Tight electrical connections don't overheat. Lubricated moving parts don't seize up.

More importantly, maintenance visits give you advance warning about components that are wearing out. Instead of facing emergency repairs during the hottest week of summer, you can plan replacements during off-peak periods when costs are lower and contractors aren't overwhelmed.

Maintenance vs Repairs: Understanding the Difference

Most homeowners don't understand the difference between maintenance and repairs, which leads to confusion about what they need and when they need it.

What Maintenance Actually Is

Maintenance is preventive care designed to keep working equipment working well. You're not fixing broken components - you're preventing them from breaking in the first place.

Real maintenance involves thorough inspection of all system components, cleaning of coils and other parts that collect dirt, testing of electrical connections and safety controls, checking refrigerant pressures, and adjusting components for optimal performance.

Think of maintenance like regular oil changes for your car. You're not waiting for the engine to seize up and then fixing it. You're changing the oil regularly to prevent engine damage in the first place.

The best time for AC maintenance is late spring, before summer heat really kicks in. This timing ensures any problems get discovered and fixed before you desperately need cooling. It also means you're not competing with emergency calls for technician availability.

When You Need Actual Repairs

Repairs become necessary when something stops working properly or starts causing other problems. Unlike maintenance, repairs address specific failures that prevent normal operation.

Effective repairs start with accurate diagnosis. Symptoms like poor cooling, unusual noises, or high energy bills can have multiple causes. Good technicians use systematic approaches to identify root causes rather than just treating symptoms.

For example, if your system isn't cooling well, the problem could be dirty filters, refrigerant leaks, electrical failures, or mechanical problems. Simply adding refrigerant without checking for leaks treats the symptom but ignores the underlying cause.

Not every repair makes financial sense. When repair costs approach 50% of replacement cost, or when multiple major components need work, replacement often provides better value. However, age alone shouldn't determine repair decisions. A well-maintained older system might justify expensive repairs, while a neglected newer system might not.

What Professional Service Should Include

Understanding what happens during professional service helps you evaluate contractors and ensure you get comprehensive care.

The Inspection that Actually Matters

Inspection is much more than a glance or visual inspection. Technicians should have special tools and diagnostic testing procedures for systematic testing of each component of the system.

Electrical testing of control circuits, safety switches and connections with meters capable of identifying problems prior to failures. Analysis of refrigerant systems with manifold gauges during full cooling cycles to measure pressures and temperatures at various locations of the cooling cycle. Testing airflow to check for performance and accessibility and to find service restrictions.

Safety testing ensures electrical connections are tight, there are proper ground connections, and protective devices respond correctly. Testing the integrity of the refrigerant system identifies leaks before they reach a level that can create major trouble or replacement cost.

Cleaning that Makes a Difference

Professional cleaning means using equipment and chemicals designed for HVAC components. Couple that with a few garden hoses, and a few household products is simply not the same.

Cleaning a condenser coil requires many techniques to get it clean without damaging the delicate aluminum fins, and often requires product that will dissolve material that plain old water will not touch.

Cleaning an evaporator coil is more complex — it is typically inside your house and tied to drainage systems where if not done properly, could cause water damage or cause any contaminants to disperse through your home's air system.

Performance Testing and Optimization:

Lastly, after cleaning and inspection, professional service should include a testing schedule following the procedure that identifies the frequency of cleaning, inspection and service intervals where testing should be done to verify the systems are performing in the optimum range, and to apply adjustments that will optimize your efficiency.

For example, a temperature differential test measures the difference between the temperature of the air entering and leaving your system. That differential should be in a particular range depending on the outside temperature and the level of humidity.

In some cases the testing for performance verification are electrical performance tests where you are testing individual components under an operational load. There are component failures that do not present until the system is in operation. For example, a capacitor may work well while the system is under a light load but can fail under a full demand.

Understanding Your System's Future

Air conditioning technology improves continuously, but that doesn't mean you should replace functional equipment just because newer models exist. Understanding your system's condition helps you make smart decisions about repairs versus replacement.

When Age Matters

System age provides context but shouldn't be your only consideration. Well-maintained equipment can justify expensive repairs even when it's old. Poorly maintained equipment might not be worth major investment even when relatively new.

Efficiency improvements over the past twenty years are substantial. Systems from the 1990s typically have SEER ratings around 10. Current equipment must meet SEER 14 minimum standards, with high-efficiency units reaching SEER 20 or higher. This efficiency difference translates to real money - replacing a SEER 8 system with SEER 16 equipment can cut cooling costs in half.

Refrigerant considerations also affect older equipment. Systems using R-22 refrigerant face increasing service costs as this refrigerant is phased out. New refrigerant costs significantly more and may become unavailable entirely within a few years.

Planning for Replacement

Smart homeowners start planning replacement years before it becomes necessary. This allows thorough research, proper budgeting, and avoidance of emergency replacement during peak demand periods.

Monitor your system's performance over time by tracking energy bills, repair frequency, and comfort levels. Gradual increases in costs or more frequent service calls often indicate replacement is becoming economically attractive.

Document all repairs and maintenance to understand your system's history. This information helps identify patterns and make informed decisions about continued repair versus replacement.

Finding Contractors You Can Trust

Service quality depends heavily on choosing the right contractor. Not all HVAC companies provide the same level of expertise or value.

Red Flags to Avoid

Never hire door-to-door contractors or anyone who uses high-pressure sales tactics. Legitimate contractors stay busy through referrals and don't need to canvas neighborhoods looking for work.

Be suspicious of estimates that differ dramatically from others without clear explanation. The lowest bid might involve shortcuts or inferior parts. The highest might include unnecessary work or premium pricing for standard services.

Avoid contractors who can't provide current licensing and insurance documentation or who demand immediate decisions about expensive work.

Questions That Reveal Competence

Ask contractors to explain their diagnostic process and what their service includes. Competent professionals can explain technical issues clearly and welcome questions about their procedures.

Request recent customer references and actually call them. Ask about work quality, punctuality, cleanup, and whether they would hire the contractor again.

Ask about warranty terms for both parts and labor. Contractors confident in their work offer substantial warranties - typically one to five years depending on the type of work performed.

Economics of Smart AC Care

Making sound economic decisions about your air conditioning requires your consideration of immediate costs as well as long-lasting values.

Cost of Maintenance

Annual maintenance, $150-300, will pay for itself by preventing repair bills of $500-2000, etc. More importantly, preventative maintenance will extend the life of your equipment from neglecting servicing which averages 8-12 years to proper maintenance extending the life of your equipment to 15-20 years.

Neglected systems not only fail sooner, but wasted energy is consumed in use. A neglected system can easily consume 25% more electricity than a system that has been maintained while providing unacceptable comfort reliability.

Emergency Service vs Planned Service

The cost of emergency service during peak business periods can be significantly higher than the cost of scheduled maintenance. Emergency service is also limiting: you may accept repairs that you would not normally tolerate because you are in need of immediate cooling.

Thinking ahead allows you the opportunity to research and compare shopping options and make a more rational decision rather than a desperate one. You also have more flexibility to negotiate than emergency repairs when you are not feeling physical discomfort.

Ignoring Problems: The Real Cost

Efforting a positive experience for your equipment first: Waiting or being procrastinative regarding problems with your air conditioning will always cost you more than paying immediate attention. Allowing a series of minor problems to develop into costly disaster.

A dirty filter, which costs $5 to replace, can lead to compressor damage that can result in a $3000 repair cost. A loose belt, which takes five minutes to tighten can break and blow the motor resulting in you spending $600 instead of the $20 it would have cost to maintain.

Refrigerant leaks that begin as small opportunities for improvement generally become more costly to repair, as a result wasting expensive refrigerant and that forces your unit to work harder using more electrical consumption. When a cooling problem arises, you often over weeks or months been paying that cost of your "leak tax" in the increased electrical energy expenses.

Water leaks from clogged drains can arise as a minor inconvenience, but can evolve into water problems causing you thousands of dollars in damages to your property. Water problems create mold growth, wood rot, and structural damages with a degree of possibilities for potentially damaging water problems.

Looking Ahead: Your Action Plan

Do what you can control now. Change filters as frequently as possible; monthly with heavy usage, quarterly or greater under normal conditions. Keep the area surrounding your outdoor units as clear of debris and vegetation as is possible. Pay attention to the sounds your unit creates and the way it operates so that you will be able to notice changes as soon as they arise.

Schedule your professional maintenance service before you enter the summer service period - not after you have developed a problem.Spring service will enable you to be ready for summer demand. Most importantly when you have noticed an air conditioning inefficiency or malfunction likely provides notice of a problem to be addressed before that problem becomes larger and actionable.

Build relationships with contractors who are competent and reputable before requiring emergency service. Research the contractors to avoid a 'cheap fix' when you are making decisions about your conditioning service selection during peak business seasons. Utilize the off-peak business periods to allow yourself thoughtful and rational decisions rather than a desperate fix!

Make sure you understand that the service for your air conditioning is not considered an expense - it is an expense for a comfort zone, expense for efficiency, expense for longevity of your equipment. The money you spend on scheduled maintenance and prompt repair will return itself to you several times over in savings in electrical bill, fewer emergency repairs, and longevity of equipment.

Your air conditioning does not need to create anxiety or an unexpected expense to you. With a little understanding and care, your air conditioning can provide years of dependable work while protecting your investment of providing comfort when you need it the most.

The Seasonal Game Plan That Works

Here's the reality about AC maintenance - timing matters more than most people think. I've seen too many homeowners wait until Memorial Day weekend to think about their cooling system, then panic when they discover problems right before the summer heat hits.

Spring Preparation: Before You Need It

March is when I start getting calls from smart homeowners who want their systems checked before summer arrives. These are the people who rarely have emergency breakdowns because they catch problems early.

Spring maintenance should include filter replacement, coil cleaning, refrigerant pressure checks, electrical connection testing, and calibration of thermostats. But it's also the perfect time to address any issues that developed during winter storage or problems you noticed at the end of last cooling season.

I remember one customer who mentioned weird noises from her outdoor unit in October. She scheduled spring service to address it, and we discovered loose fan blades that would have failed completely during the first heat wave. A $30 repair in March instead of a $400 emergency call in July.

Fall Wrap-Up: Protecting Your Investment

Fall maintenance gets overlooked because cooling season is ending, but it's actually crucial for system longevity. After months of heavy use, components show wear that needs attention before next season.

Post-season service reveals problems that developed during heavy summer operation. We often find capacitors that are weakening, motors showing signs of strain, or refrigerant leaks that started small but will get worse over winter. Fixing these issues during off-peak periods costs less and ensures you're ready for next year.

If you have a heat pump that provides both heating and cooling, fall service is absolutely critical. These systems work year-round and need attention before switching to heating mode.

Climate-Specific Strategies

Your location dramatically affects what your AC system needs and how often it needs attention. What works in dry Colorado won't necessarily work in humid Florida or dusty Arizona.

High-Humidity Areas: The Moisture Challenge

In places like Houston, New Orleans, or Miami, your AC works overtime removing moisture from the air. This creates specific maintenance needs that don't exist in drier climates.

Condensate drainage becomes critical when your system produces gallons of water daily. Drain lines clog faster with algae and biological growth. Drain pans overflow more easily. Indoor air quality suffers when moisture creates mold and mildew problems.

I've learned to recommend monthly drain line treatments in humid climates instead of the semi-annual treatments that work fine in drier areas. UV lights installed in ductwork help control biological growth that thrives in moist conditions.

Humidity also affects comfort in ways that surprise people. Air at 78 degrees with 40% humidity feels more comfortable than air at 75 degrees with 70% humidity. Understanding this relationship helps you set thermostats more efficiently.

Desert Environments: Dust and Heat

When I worked on AC systems in areas like Phoenix and Las Vegas, I learned that extreme environments require specialized approaches. When it is 115 degrees outside, even the best equipment struggles to keep indoor temperatures normal.

The rate of dust infiltration constantly increases in desert environments. Filters need to be changed monthly instead of quarterly. Coils accumulate dust that is even more restrictive than normal dirt or debris. Dust compromises electrical components and causes them to fail quicker.

During extreme heat events, I advise customers to set their thermostats 3-5 degrees higher than normal. While few people can tell the difference between 72 and 77 degrees, stress placed on equipment can and will decrease considerably, saving money.

Coastal Areas: Corrosion Concerns

Salt air conditions create additional challenges when working on AC equipment. Metal components made of galvanized and aluminum are subject to accelerated corrosion, inspections and preventative measures are required more often than inland systems.

In coastal locations, condenser coils experience corrosion from the inside out and develop pinhole leaks that can only be detected after damage is done. Electrical connections fail faster because of the salt content. Fasteners and anchor hardware fail quicker too.

Regular cleaning of coils becomes extremely important in coastal locations, not just for efficiency, but for longevity. Specific anti-corrosive treatments are available that help protect components subject to salt air exposure.

Advanced Troubleshooting Techniques

I have developed a more systematic approach to looking at AC problems over

time, and I probably have some methods you can utilize to identify the root cause of an AC failure instead of just addressing symptoms.

The Temperature Test That Tells All

One of the most useful methods of analysis you can use is checking your temperature differentials at different points in your system.A normal temperature drop across your evaporator coil is usually from 15-20 degrees, depending on the humidity.

If your temperature difference is too low, your system is not pulling enough heat from the air. The possible causes could be low refrigerant levels, dirt on the coils or filters, air flowing restrictions, or failing components. If your temperature difference is too great, you could have too much air flowing restriction or refrigerant issues.

I keep a digital thermometer in my truck, and I use it a lot. Homeowners can conduct similar testing with inexpensive digital thermometers and keep track of their system's performance over time.

Electrical Diagnosis Without Being Shocked

Besides the constant problems homeowners reach out about regarding electrical components of their system, there are a few simple items they can check that may indicate electrical issues developing.

Have you noticed flickering lights in your home when you turn on the AC? This indicates potential electrical supply issues that could cause damage to your equipment! Do you smell burnt stuff from the vents or your electrical panel? Overheated connections! Circuit breakers kept tripping? Your electrical supply may have unsafe conditions, and your circuit breaker is protecting you from them!

If you see or smell any of these alarm bells, turn off your system and get someone to service it. Electrical issues with AC systems can very dangerous and potentially lead to fires or electrocution if not address properly.

How Systems Go Through Cycles

Normal air conditioning operation follows cycles that tend to be standard in their length, and after many years, you will start to notice problems that develop as they occur on a cycle.

Under normal conditions, systems should run 15-20 minutes per cycling process: until the thermostat has been satisfied.

Short cycle (very short run times) a system is typically oversized, or electrical or refrigerant conditions are causing it. Systems that only run at capacity and are not fulfilling the thermostat could have refrigerant leaks, capacity problems, or excessive heat loads.Knowing what is normal for your specific system means you will know when things change, or when something new require your attention.

The Business of AC Service

Knowing how the HVAC trade works means that you can get better service, and be able avoid the traps that your home or business might fall into when it comes to common charges incurred by homeowners.

How Contractors Make Money

Most HVAC contractors make the majority of their profit selling equipment rather than doing service calls. This creates a conflict of interests for contractors when they are recommending repairs or replacement. Understanding this conflict of interests can help you navigate contractors' proposals in an unbiased fashion.

When the profit margins for service calls are smaller, some less scrupulous contractors will take advantage of this and recommend new equipment instead of patterns of service and then repairs. Some contractors are more honest and want to build the service relationship over time, and will recommend appropriately when you are making decisions about repairs versus replace.

Ask contractors how they differentiate an appropriate repair versus needing to replace. A good contractor will give you objective criteria for evaluating repairs based on the cost of a repair relative to the age/value of a system, beyond their own need to sell you a new replacement.

The Realities of Seasonal Pricing

The price of HVAC service has huge amounts of fluctuation in cost relative to demand. Emergency calls in extreme heat wave scenarios may cost four times more than a normal service call would have cost during standard moderate conditions. The availability of parts can also have an effect on how much contractors charge customers in emergencies; normal or "regular" components have a lower costs than specialty components that are ordered specifically for customers maintenance.

In extreme exposure and extreme demand for HVAC services, plan in advance for seasonal repairs and replacements during shoulder seasons when the contractors will have more time and will be more negotiable on prices and costs. You will also get better technician availability, service, and repairs when they are not in emergency mode or immediate service demands.

Warranties

The warranties you have on your equipment can also establish a spectrum that creates discussions about repair decisions in a service experience. Knowing what a warranty is, and valuing them as warranties helps prevent unpleasant surprises for homeowners. The value in most equipment warranties is limited to parts, and does not include the cost of labor for repairs.Some warranties lose coverage if unauthorized technicians perform any service on the equipment. Be sure to keep warranty documents organized, read carefully what is covered and what is not and make sure you are aware of all service requirements before any issues arise. Some warranties will cancel coverage if yearly maintenance does not occur, making service contracts a good option simply to protect the warranty of the equipment.

Technology and Smart Systems

Modern air conditioning systems have improved features that dramatically enhance convenience and energy efficiency when seemingly used correctly, but they can also create different inherent problems.

Smart Thermostats That Actually Help

Smart thermostats do allow for potential energy savings of around 10-15% when they are programmed correctly. The downfall is that most homeowners do not or cannot utilize the benefits of their smart thermostats. By learning the schedule your family keeps and automatically adjusting temperatures accordingly, smart thermostats can save energy while maintaining the same level of comfort.

Remote monitoring will let you know if there are developmental issues prior to system failure. There are smart thermostat systems that actually review your data and note deviations and recommend service when the patterns change.

Smart thermostats will create problems if they are not installed correctly or programmed properly. Newer thermostats sometimes have compatibility issues with older products and cause erratic operation and it may not be easy to troubleshoot the problem.

Zoning Systems and Variable Speed Equipment

Zoning systems can allow each area of the house to be controlled independently, promoting comfort and efficiency. Variable speed equipment typically operates at lower speeds most of the time which provides better control of humidity and more steady conditions for temperature.

Both of these technologies are only useful if they are designed and installed correctly. A poorly designed zoning system can consume more energy and create comfort issues. Variable speed equipment requires different servicing techniques and not all technicians posses the necessary skills.Health and Indoor Air Quality: Impacts

Your air conditioning system will impact indoor air quality in ways that affect your family's health and comfort more directly than you probably think.

The Filter Factor in Air Quality

Air filters (i.e., HVAC filters) do more than simply protect your equipment - they clean the air that your family breathes. Our inexpensive filters provide little to no cleaning of the air we breathe, and our more expensive high-efficiency air filters have the potential to remove allergens, bacteria, and other harmful contaminants from the air we breath.

In severe cases, filtering the air that is moving through your system to the point of severely restricting airflow and damaging your equipment can void manufacturer warranties. For this reason, the challenge is to find the most efficient filter that your equipment can handle while not providing too little airflow for your system to function properly, ideally, the airflow should meet or match the equipment manufacturer's specifications.

In cases, some families benefit from distancing dedicated air purification systems that coordinate with their AC equipment. UV light, electronic air cleaners, and whole-house HEPA systems can dramatically improve indoor air quality for individuals suffering from allergy and/or other respiratory ailments.

Humidity Control and Comfort

Humidity control (or humidity control systems) is just as important as safe operation, as still have. Humidity control affects our comfort, health, and operating costs and energy efficiency. It can easily produce a mold problem when too much is present and is a variable that influences how warm temperatures feel comfortable. Not enough humidity makes our skin dry, irritating sinuses and respiratory systems, and creating static electricity problems in the environment depending on temperature conditions.

Your air conditioning naturally removes humidity while operating, however a system that is too large for its intended application (new construction or a retrofit renovation), does not provide enough run time for the dehumidification process to operate effectively. Dedicated dehumidification equipment can maintain more precise control of humidity levels where air conditioning alone is ineffective for some climates.

Long-Term Funds Planning

Smart homeowners can anticipate replacing their air conditioning system financially or economically years before it becomes necessary. You have to think ahead and not wait for a true emergency situation that costs you more with poor decisions that will cost you money on a new central air condition system.

Life Cycle Cost Analysis:

The upfront costs of available equipment is reflective of hourly or monthly "cost to own," i.e., the cheapest equipment is rarely the cheapest equipment to own, all things considered at the end of life and re-investment time.While energy-efficient systems have a higher first-cost, they provide lower operating costs and equipment life that saves you money.

Calculate the total ownership including purchase price, installation costs, annual energy usage, the expected maintenance costs and projected equipment life. This analysis can show that more efficient equipment is a better value, even if the first-cost are higher.

When comparing your options, include available rebates and available tax credits in your analysis. Many utilities will offer substantial rebates for high-efficiency equipment, as well as tax credits available at the federal level, that can greatly reduce your effective costs.

Start budgeting for replacement

When should you start to budget for AC replacement? When your current system is reaching 8-10 years old, even if it's working fine. By putting money aside for your AC replacement, from $200-300 per year, you will have created a replacement fund, so when it's time to replace it won't be a huge financial shock.

Pay attention to the repair costs as old systems age. If your annual repair bill exceeds $500-600 per year in repairs, replacement is usually a much better value rather than continuing to repair an older system.

Preparing for emergencies

Knowing what to do when your AC fails completely can protect the health of your family and help avoid any additional damage to property.

Heat Emergency Procedures

The total failure of your AC can put your family, especially elderly relatives or individuals with electrical conditions, in serious health risks during heat waves. Have a plan, with temporary cooling options as well as a temporary alternative arrangement for your family in case of high heat periods.

For cooling, minimize your efforts to one or two rooms with portable fans or redeployable window units or other temporary means. It is good practice to close or seal off unused parts of the house to focus whatever cooling capability you can obtain.

Be aware of symptoms of heat exhaustion and heat stroke.Signs of confusion, nausea, fast pulse, high temperature need immediate medical help.If you see someone is showing these types of symptoms don't wait on your AC repair people.

Equipment Protection from Power Outages

A long power interruption can index the AC systems into damage when it is restarted, especially if the power restoration process has support voltage oscillation. Disconnect your AC from power prior to restoration, then wait several minutes until a stable condition is restored to power, before turning you AC system back on.

Some surge guard devices are designed specifically for AC equipment to protect them against the voltage spikes related to restoration.These devices are minute costs compared to the cost of equipment replacement, and provide some great insurance against electrical failure.

Your Future Home Cooling

Knowing about technology trends, will help you make decisions that keep a sense of value as the industry changes.

The Evolution of Heat Pumps

Today’s heat pumps perform effectively in climates that are much colder than those for which they were initially designed.In many regions this also means that they can replace a traditional AC only system.In fact, cold climate heat pumps can work at ambient temperatures down to -15 deg. Fahrenheit.

An evolution of technology means that heat pumps may be able to increasingly provide us both heating and cooling solutions in climates in which they previously could not compete with separate systems, in many cases with considerably greater efficiency with either and/or both heating and cooling equipment which are designed for a specific purpose.

Refrigerant Improvements

Beyond this, the industry continues to develop refrigerants that are more environmentally friendly and mission critical to making our HVAC products perform better and are more serviceable than the refrigerants currently in use.These changes impact longevity of service and cost of service calls for equipment we previously purchased, while at the same time improving the performance of new equipment.

Keeping pace with refrigerant changes will assist in planning equipment replacement and allowing us to make responsible repair decisions for larger equipment that is being phased out.Increasing service costs are in our future with equipment that employs R-22 refrigerant, as the availability of R-22 becomes issues over the next one or two years.

Your Pathway Forward

What separates homeowners, who enjoy decades of service from their cooling equipment, from those who struggle with an unremitting problem is the degree of information, consistency, and quick response when issues develop.

Now is the time to implement what you now know.The first step will be to change filters based on who you are and the unique parts of your environment of who you are, not just based on some generalized recommendation.Schedule your professional maintenance shoot before the peak of the season, and not after any equipment issues develop.Awareness of sound and operational performance, will very quickly give valuable clues to when your equipment needs attention.

Plans should begin to cultivate a good working relationship with qualified service practitioners when your equipemnt is functioning well, and NOT during a panic mode.Most contractors go through a careful thought process of qualifying available contractors though research and asking the right questions.In a service situation, its not be qualified or recruited on performance and ethical behaviours, but because they are the cheapest.

Most important, we believe AC service is an investment in your personal comfort, increases the value of your home, and value to the wellness of your family.If you pay for proper preventive maintenance procedures, and repair calls for ailments when they do arise, the money spent will be returned multiple times over, as the result of lower energy costs, fewer emergency calls, and longer equipment life cycle.

Your air conditioning system is capable of providing decades of service, if properly nurtured, and a recognition of the value is placed on servicing, and ensuring a continuum of professional service.With the knowledge you have gleaned, you will have an advantage over the general population of homeowners now, in accessing the most value from your investment in a cooling system.